Hello All,

A few months ago I got the idea to upgrade old computer speakers with a wi-fi module. After some research I ended up with the Arylic up2stream v3 as the Wi-fi/Bluetooth module. Since this was my first project like this, I didn’t want to risk buying expensive speakers which I might ruin, so I used old computer speakers. I also wanted to give the speaker a new design since it was outdated. The goal was to create a design which would allow the left/right speakers to be combined as one. After some trial and error about what works and what doesn’t, I ended up with a design based on the Sonos play 5. I had to modify and change the design to fit my 3D printer. The main limitations are the build plate and printing with as little as possible support.

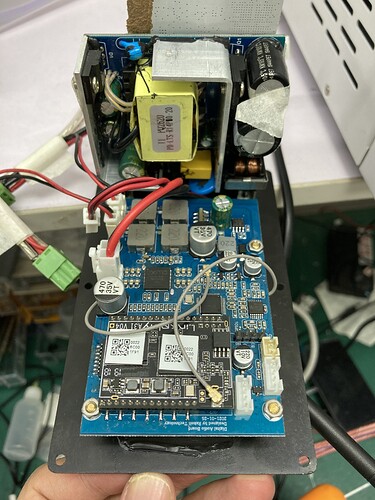

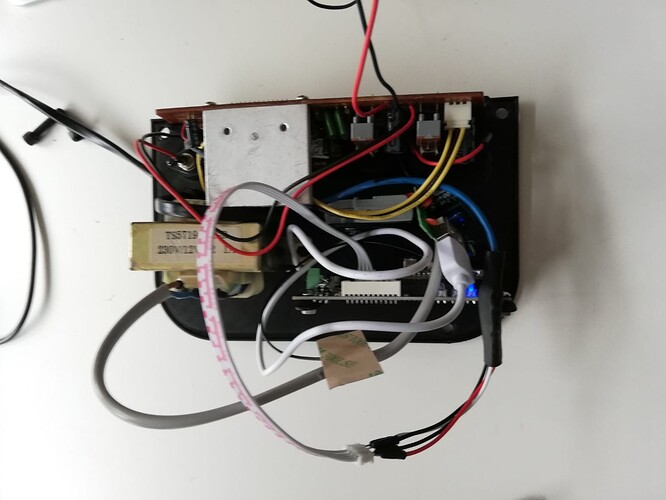

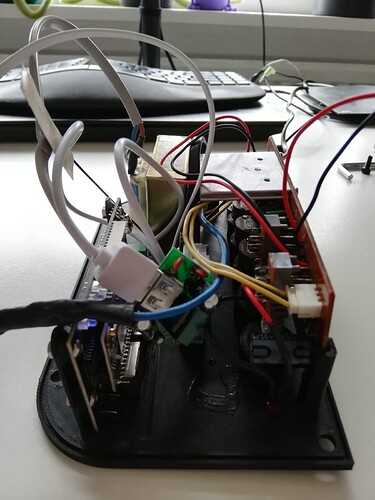

Next up, I needed to do the wiring. The Arylic up2stream v3 requires a 5v power supply. The speakers required a 12v power supply. I ended up splitting the incoming 230v/240v power cord, one end would go to the transformer of the speakers, the other to a (stripped) smartphone adapter. A simple usb cord then goes to the power supply of the Arylic up2stream v3. Lastly, the connection between the Arylic up2stream v3 and circuit board of the speakers is made via the amplifier port on the board. This leaves the 3.5 jack-out port free to connect a second system if needed. The results are shown below (the cable management hasn’t been done yet).

Figure 1 - Top view of the cicuitboard, transformers and Arylic up2stream v3 connected to the backboard of the speaker. The Arylic up2stream v3 can be seen at the bottom right.

Figure 2 - Side view of the cicuitboard, transformers and Arylic up2stream v3 connected to the backboard of the speaker. The Arylic up2stream v3 can be seen at the bottom left.

After having this part working, it was time to finish the design. I wanted to connect the two parts of the speakers using magnets (bad with speakers I know, but I assumed/hoped they were weak enough to not cause noticeable disturbance). Secondly, I wanted to 3D print the front grill as well and make it attached with magnets in order to easily take it off if needed. Lastly, when combined there should be a third grill which should cover both speakers to make them more coherent. This put some difficulty on the design since my built plate could only handle 300mm by 300mm (and 400 in height, but that is not a stable print). The final results are shown below.

Figure 3 - Combined speakers with a single front grill.

Figure 4 - Speakers without the grills.

Figure 5 - Speaker orientation options. In addition, some magnetic feed can be attached to the horizontal mode to lift the bottom at the front a little (the feed are connected to the back).

Figure 6 - Back of the main speaker with the up2stream pro V3 at the top left.

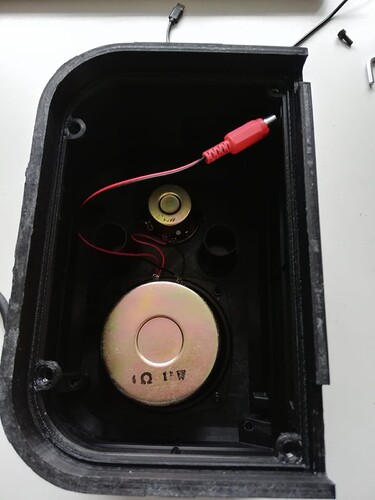

Figure 7 - Speaker without the back cover.

The speakers work quite well, I haven’t noticed any issues with the up2stream V3 module. However, since I have used old speakers, the quality can be a bit better. In order to temporarily solve that, I connect a second (2.1) system via the 3.5 jack out on the back, this works perfectly and really gives more depth to the sound. I am thinking of doing a similar project in the future with self-built Hi-Fi speakers. Overall, I definitely enjoyed the experience for my first DIY project with regards to speakers.

), great job. We would release a plate for speakers soon, very easy to integrate, so you only need to consider the casing design and speaker, maybe less fun for wire connecting and soldering

), great job. We would release a plate for speakers soon, very easy to integrate, so you only need to consider the casing design and speaker, maybe less fun for wire connecting and soldering